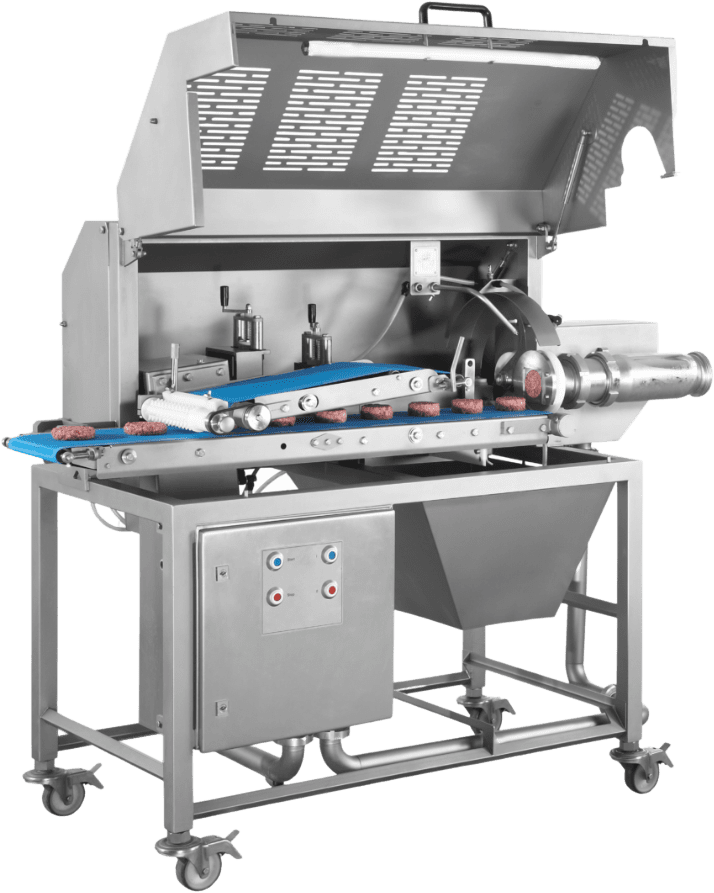

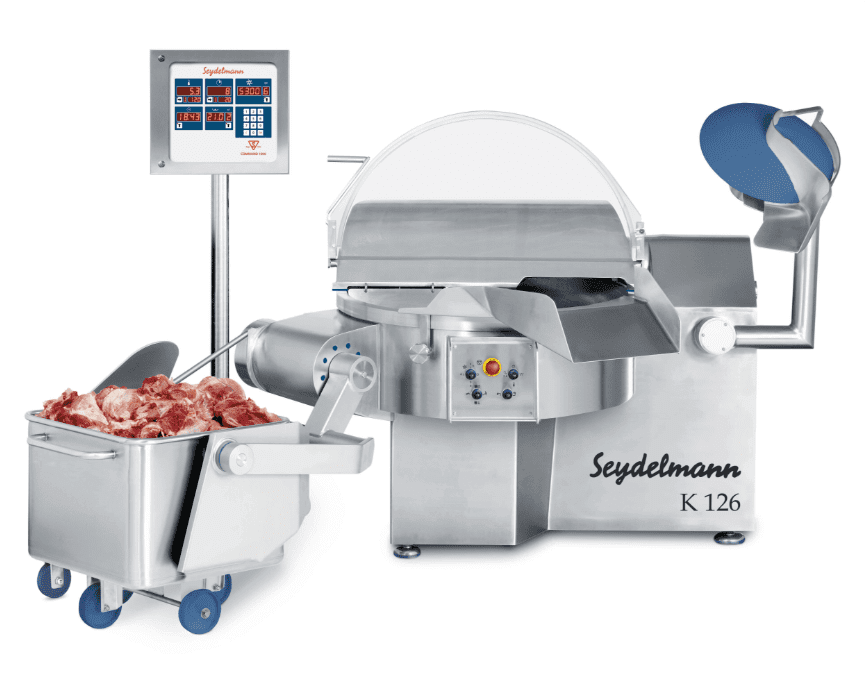

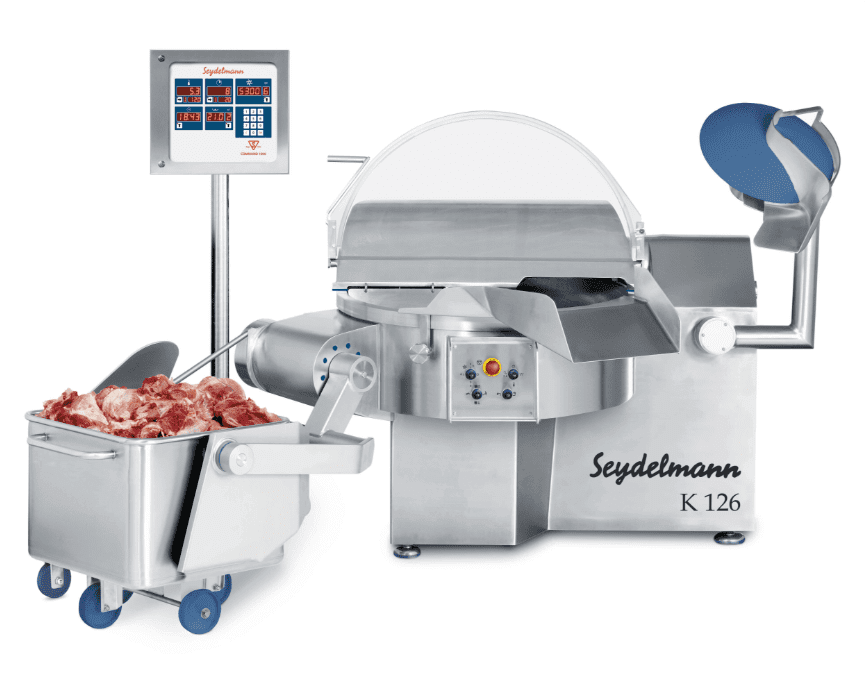

Preparation

The Seydelmann Bowl Cutters should be a staple in every food factory, producing supreme quality products across a range of applications. The flexibility and efficiency brought to numerous processes is worth the time to explore; chopping, emulsifying, mixing and blending, along with other options including cooling, cooking, melting, and thermisation, vacuum drying, evacuating, and granulating.

Let’s work together on the best solution!

Mixers are ideal for combining and standardising source materials with spices and other additives and the Seydelmann offering can be used for many different applications.

Contact a member of our team to find out what other benefits can be achieved through the use of a Seydelmann Bowl Cutter and Mixer.

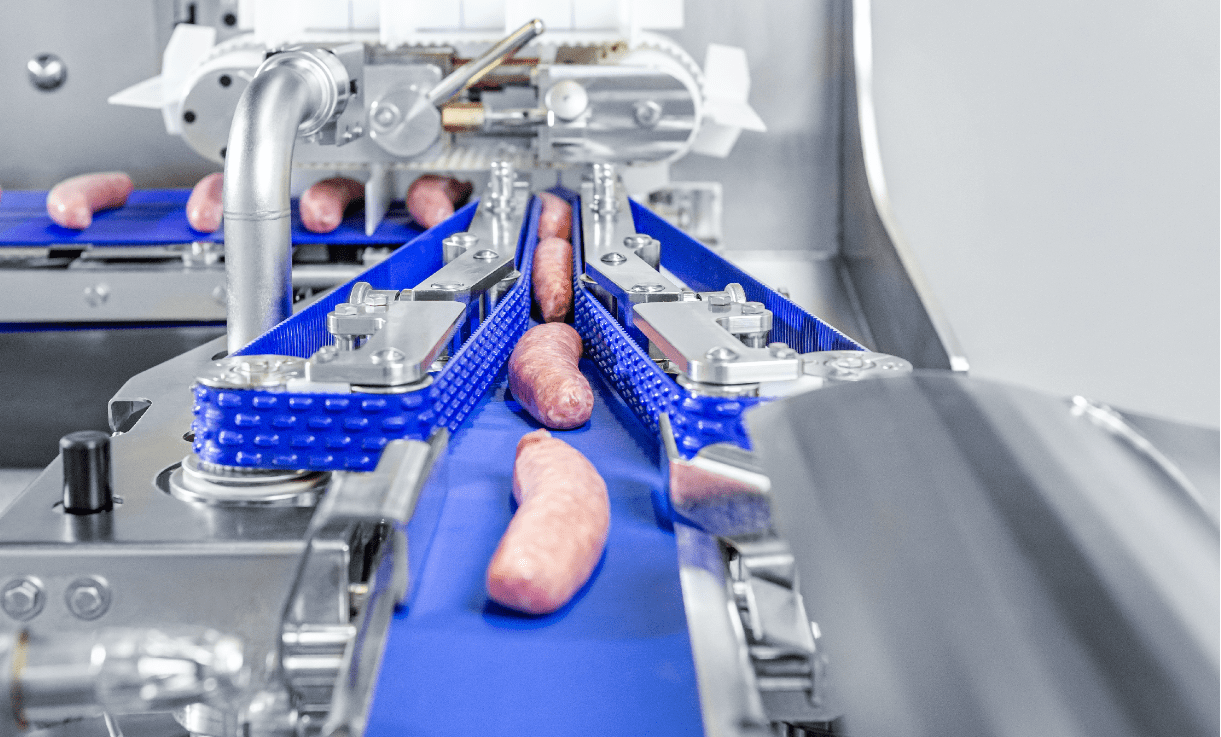

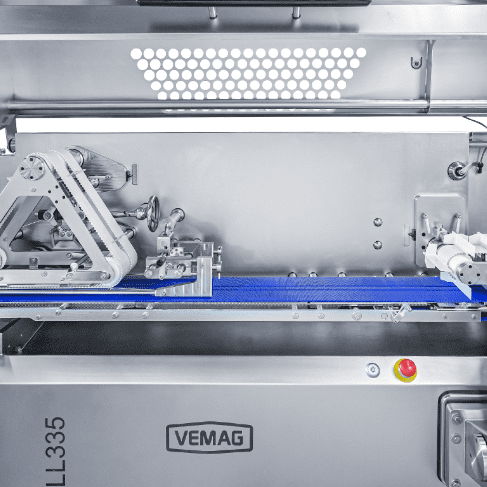

Inline Grinding & Stuffing

The Vemag Inline Grinders provide the last cut directly before filling and linking. Driven by Vemag’s innovative double screws, the grinder separates and removes sinews and bone particles. The process will leave you with a mix of excellent quality, great colour, a clear structure and even particle distribution throughout your product.

If you want to produce sausages, regardless of batch size and casing type, we have solutions for your needs.

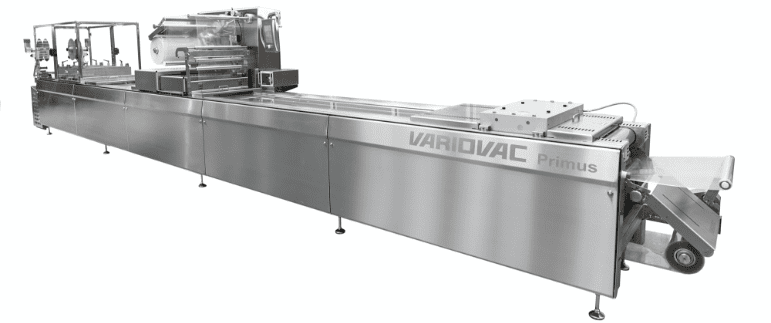

Packaging

Whether it involves vacuum, MAP, skin, shrink packaging or hot filling – the VARIOVAC range of packaging machines stands out with excellent performance in all areas. It supplies high-quality packaging reliably and efficiently, and already does so from a machine length of just 3 metres! In the process, it sets benchmarks with regards to technology and performance. All VARIOVAC machines work with the highly developed VARIOVAC RapidAirSystem. The machines offer best-in-class performance and application flexibility.