Preparation

The Seydelmann Bowl Cutters should be a staple in every food factory, producing supreme quality products across a range of applications. The flexibility and efficiency brought to numerous processes is worth the time to explore; chopping, emulsifying, mixing and blending, along with other options including cooling, cooking, melting, and thermisation, vacuum drying, evacuating, and granulating.

Let’s work together on the best solution!

Mixers are ideal for combining and standardising source materials with spices and other additives and the Seydelmann offering can be used for many different applications.

Contact a member of our team to find out what other benefits can be achieved through the use of a Seydelmann Bowl Cutter and Mixer.

Inline Grinding & Forming

The Vemag Inline Grinders provide the last cut directly before filling and linking. Driven by Vemag’s innovative double screws, the grinder separates and removes sinews and bone particles. The process will leave you with a mix of excellent quality, great colour, a clear structure and even particle distribution throughout your product.

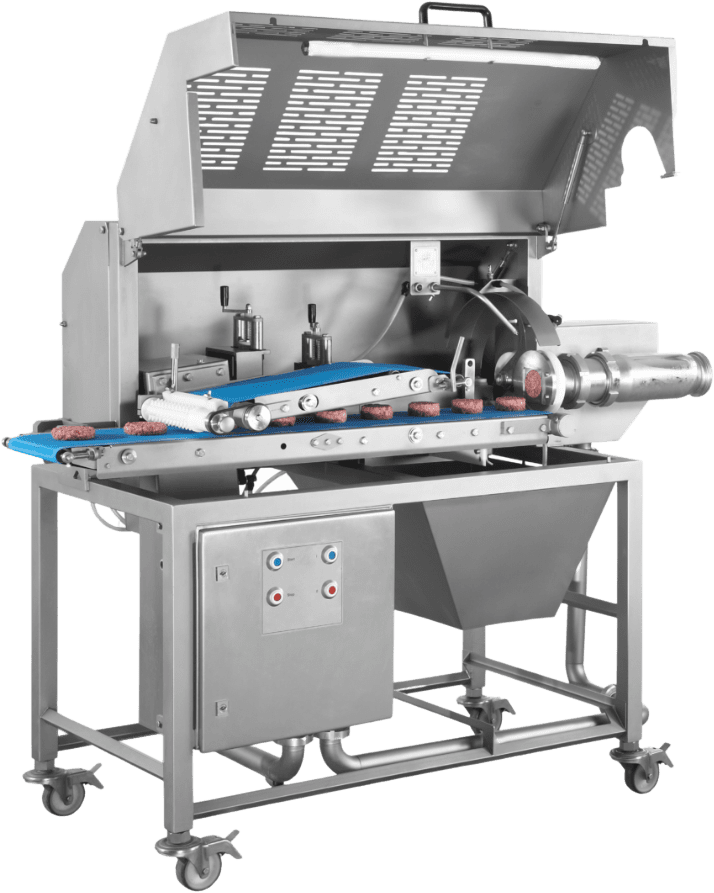

Vemag’s FM250 produces shaped products from meat, vegetable and plant-based mixtures and features:

• Quickly interchangeable nozzles for different shapes

• Portioning rate of up to 300 portions per minute

• Products that keep their shape even after the cooking process

• Products with excellent texture and natural bite thanks to the gentle transportation of the product

• Can be combined with additional Vemag systems such as the separation grinder or multi-tray loader

• Minimal setup and cleaning times for cost-effective production

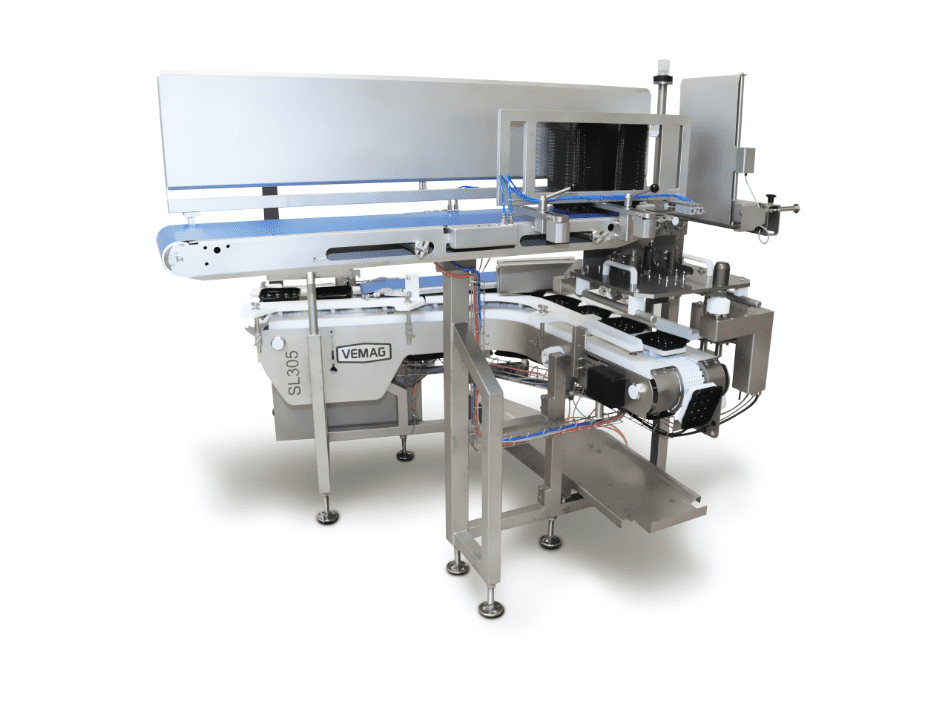

VEMAG SL305

For fully automatic and efficient packaging of your burgers, look no further than the SL305. Utilising a simple tray denester, the machine automatically deposits approx. 180 burgers into trays per minute, preparing them for tray sealing further down the line and removing the requirement for any manual intervention.

Suitable for various packaging formats, burgers can be positioned one after another, in stacks or in overlapping rows. Flexibility really is the key with the SL305. In addition to burgers; meat balls, kebabs, meatloaf, minced meat and much more can be loaded automatically into trays, future proofing your investment.

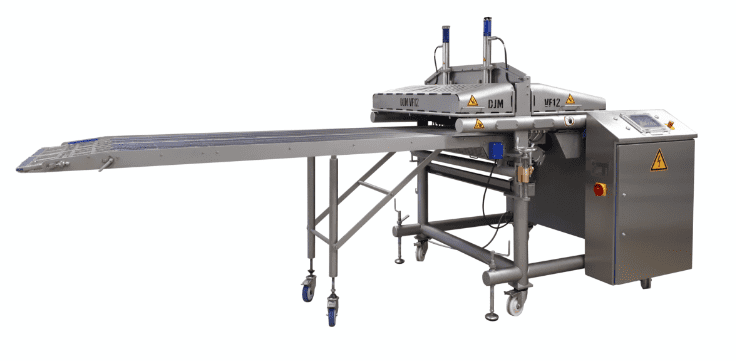

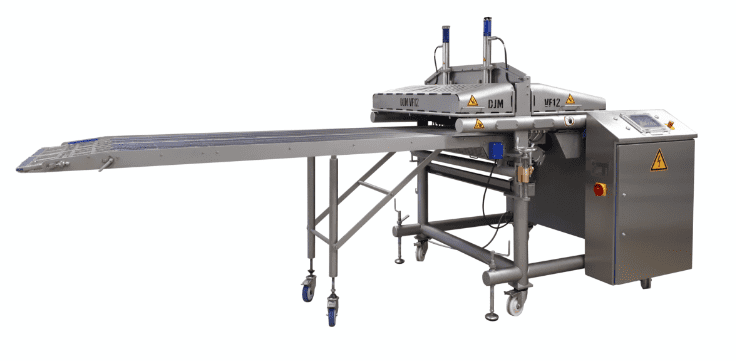

DJM VacForm

DJM has developed a complete line of VacForm machines for the production of 10:1 and 4:1 burgers. Schnitzels, chicken nuggets, fish sticks and vegetable products are also possible. These machines can produce more than 1,400 kg of chicken nuggets and more than 4,000 kg of burgers per hour. The patented DJM pressure distribution system ensures extremely small weight variations, which prevents product loss and optimises economic production. The machines are also available with an automatic paper insertion system (paper interleaver); the products can be produced in stacks with a ‘sheet of paper’ between each product so they are always easy to separate from each other. We can build machines to match your production situation, requirements and possibilities.

Packaging

Whether it involves vacuum, MAP, skin, shrink packaging or hot filling – the VARIOVAC range of packaging machines stands out with excellent performance in all areas. It supplies high-quality packaging reliably and efficiently, and already does so from a machine length of just 3 metres! In the process, it sets benchmarks with regards to technology and performance. All VARIOVAC machines work with the highly developed VARIOVAC RapidAirSystem. The machines offer best-in-class performance and application flexibility.